Review

Jet Bandsaw – What Are the Components of a Bandsaw?

Jet Bandsaw – What Are the Components of a Bandsaw?

Most workshops in residential garages and basements and light industry have a bandsaw that can cut wood, metal or plastic. The bandsaw also can be used for resawing large pieces of lumber.

All of the saws have two-position fences that can stand upright for resawing or lie flat to accommodate narrow rip cuts. They also have hex-wrench access holes for adjusting the lower blade guides.

Blade

The blade of a bandsaw consists of a continuous strip of metal with teeth along one edge that cuts various workpieces. The bandsaw is used for woodworking, metal cutting and other applications. It is a versatile tool that allows you to cut curves and shapes that are difficult or impossible to do with a conventional saw. The bandsaw can be used to make both straight and curved cuts, and it can also be used to make notches or bevels in workpieces. It can be fitted with a miter fence for precise cuts.

The jet bandsaw comes with a solid cast iron base and head that provides full blade support to eliminate deflection or vibration, making it more accurate than lesser models. The saw’s combination oil bath and gear reduction power train reduces noise, vibration and heat while increasing blade life. Its convenient, centrally located control panel puts major functions right at your fingertips. Its swiveling table and blade guide post allow for greater flexibility with your projects. The saw is prewired for 115V electrics and includes an easy-to-use drive belt tensioner that does not require tools.

The 14-Inch SFX steel frame bandsaw from Jet redefines the line between functionality and affordability. It combines tubular steel construction with exceptional resaw capacity, large table dimensions and a long list of features designed to streamline woodworking for both professionals and hobbyists. Its swiveling table allows for miter cuts of up to 45 degrees and can be connected to a dust collection system with its dual 4-inch dust ports. The saw is also equipped with a heavy-duty fence system that gives you confidence when resawing or making other complex cuts.

Motor

The motor of a jet bandsaw drives a continuous band of metal with teeth along its edge and cuts workpieces. These workpieces can be curved or straight. The head of the saw can be pivoted to make mitered cuts. These bandsaws cut a variety of materials including wood and metals.

Jet’s 14-Inch SFX steel frame bandsaw has a lot of features that can streamline woodworking for the serious woodworker. This machine boasts best-in-class resaw capacity, large table dimensions and a list of other functions that can simplify your woodworking tasks.

A cast iron table provides sturdiness and stability when cutting. It tilts 0-45 degrees for a range of bevel cuts and includes a miter slot and a miter gauge. It is prewired for 115V service and includes a paddle off-switch and a safety key. The saw also has dual 4’’-diameter dust ports to connect it to a vacuum system.

This heavy-duty saw features a combination oil bath and gear reduction power train for consistent cutting and longer blade life. The combination of these features makes this one of the most precise and durable machines on the market. It also has a cast iron base that is reinforced with tubular steel. This helps reduce vibration that could alter the cut.

The ELITE swing away panel relocates most saw controls to a single location, making them easy to operate. This eliminates the need to move the saw to access different functions and improves overall function and performance. The saw is backed by a two year warranty. It is a great choice for fabricators and production workers who need to cut a wide range of materials. This saw can cut round and rectangle steel tubing up to 10” at 90 degrees and 6″ pipe at 45° both ways.

Table

The table is a critical component of a bandsaw. It supports the workpiece and helps prevent thin slices of wood from jamming in between the blade and the plate during a cut. This can cause splintering and chipping. A quality table is made of a sturdy material such as steel or cast iron. The table also has a set of guides to guide the blade during cuts. A quality table can save time and effort by allowing the user to make accurate, smooth cuts.

The JET 14-Inch SFX Steel Frame Bandsaw redefines the line between functionality and affordability. Its tubular steel construction delivers exceptional resaw capacity and large table dimensions. The saw includes a host of premium features to streamline woodworking for woodworkers of all experience levels.

This well-equipped saw has a large 360 square inch cast iron work table and a heavy-duty fence system with easy-to-read laser-etched height scales and micro-adjust feature. The fence can be positioned in vertical position for resawing or horizontally to make precision cuts.

The saw’s deluxe design includes lower and upper ball bearing guides to stabilize the blade, as well as an easily adjustable LED work light for better visibility. The saw’s quick release blade tension makes it easy to change the blade. A convenient resaw guard and miter gauge are included. This well-rounded saw is a smart investment for any woodworker’s shop. It can handle a wide range of projects and is suitable for both resawing and crosscutting. Its compact size and 1 hp motor enable it to fit easily into most shops, even those with limited space.

Fence

The fence is a barrier between two areas of land, usually made of wood or wire supported by posts. It is used to prevent people or animals from entering or leaving an area. A fence can be topped with variegated ivies to improve its appearance.

In Charles Dickens’ 19th century novel Oliver Twist, Fagin is a fence who recruits homeless boys to be pickpockets and sells their stolen goods for him. The word fence is also used in the sense of an organization that sells stolen goods, or to sell goods at a price higher than the normal wholesale market rate. A fence may also conceal or destroy serial numbers on the stolen goods to prevent them from being identified by police or by other fences.

Designed to perform, this bandsaw offers the premium features and superior performance you need to tackle more ambitious projects. With best-in-class re-saw capacity, greater throat depth, and increased horsepower you’ll be able to confidently resaw larger boards with ease. The heavy-duty cast iron worktable is precision-ground for flatness and features a miter slot, miter gauge, and micro-adjust dial. The large, independently adjustable guides are tool-less for quick set up. The saw is powered by a robust 1-3/4 HP, single-phase motor and comes prewired for 115V service. It’s equipped with a paddle off-switch and safety key, as well as dual 4″-diameter dust ports to connect to a vacuum system.

The prices that fences pay to thieves depend on norms and on the actual value of the goods being sold. Vulnerable thieves may be willing to accept less than 20% of the value of an item, while professional thieves and those who specialize in particular types of goods command significantly higher prices.

Safety

An important part of a bandsaw operator’s job is to ensure they follow all safety protocols and procedures in order to prevent injury. Many newer band saws come equipped with vision or contact-sensing systems that kill power to the blade within milliseconds once triggered, greatly decreasing the chance of an operator’s hand getting too close to the cutting edge. This new breed of automatic band saws drastically reduces the number of injuries caused by traditional, hand-fed machines.

Another important safety measure is to ensure the saw’s guard covers the entire working portion of the blade during operation. This will minimize the risk of an operator slipping or trips and coming into contact with the blade while feeding meat into the machine. Adding gates and vision shields to the bandsaw can also help protect an operator’s hands from coming too close to the blade during operation.

In addition, a good bandsaw will have multiple machine safeguards, such as an emergency stop button or lever, which can be accessed in the case of an uncontrolled incident. These are often required by OSHA to be accessible for all machinery and will allow an operator to shut down the machine quickly, reducing the severity of any injury and eliminating the potential damage to the workpiece or machine.

The Jet 14-Inch SFX Band Saw is a premium woodworking tool that’s loaded with operational and safety features designed to make it a great choice for serious woodworkers. Its tubular steel construction, resaw capacity and large table dimensions offer exceptional performance. It comes prewired for 115V service and has a paddle off-switch and safety key. It also has dual 4”-diameter dust ports that can be connected to a shop vacuum system for cleaner, safer operation.

Review

Surgical Tech Jobs

Surgical Tech Jobs

Surgical tech jobs offer an exciting and rewarding career in the health care industry. Also known as operating room technicians, surgical technologists work alongside surgeons and other healthcare professionals throughout a surgery.

A career as a surgical technologist starts with completing a certificate program or an associate degree. Surgical technology programs combine classroom study with hands-on clinical training to prepare you for the OR.

Surgical Procedures

When you think of a surgery, you probably imagine a surgeon wearing blue gloves and a patient on the operating table. However, surgeons and nurses aren’t the only individuals who perform lifesaving surgeries. Surgical technologists, or scrub techs, work with doctors to ensure that operations run smoothly. They’re primarily responsible for pre-operation prep, operating room maintenance and post-surgery care.

Surgical technologists receive their training through programs offered by community and junior colleges, vocational schools, universities and hospitals. The programs can take up to two years and culminate in an associate degree. They’re also required to complete a national certification exam after graduating.

According to Zippia, the most important skills for a surgical tech include attention to detail, teamwork and the ability to work well under pressure. They need to be able to follow strict protocols and pay close attention to the surgeon’s instructions. In addition, they must be able to anticipate what the surgeon needs during procedures.

Another vital skill is emotional resilience. Because the surgical environment is high-stress and often carries with it the potential for a complication, surgical techs must remain composed and focused. This helps them provide support to their colleagues and patients.

Once the operation is completed, surgical technologists apply bandages to the patients and assist in moving them into recovery rooms. They’re also responsible for cleaning and sterilizing the surgical instruments. This is a crucial part of maintaining a safe surgical environment and helping to lower the risk of infection in patients.

Because they’re so closely involved with the surgical department as a whole, surgical technologists are qualified to fill in for other jobs within the facility, including administrative positions. For example, some surgical technologists become supervisors of other sterile processing staff or even lead the entire unit. Others may pursue a bachelor’s degree in healthcare administration to further their careers.

This is particularly popular for those who don’t want to spend an extended period of time in a medical school program. It also allows people to get started in a career in the healthcare industry without the extensive financial and educational commitments that are often associated with becoming a doctor or nurse.

Preparation

As a scrub tech, you prepare the operating room for surgery by sterilizing instruments and preparing surgical kits with special drugs, solutions, and supplies. Surgical technologists often complete formal training programs that take nine to 24 months and include classroom instruction, supervised clinical experience, and coursework in anatomy, physiology, professional ethics, microbiology, and pharmacology.

The preparation part of your job is crucial because even a minor mistake could cause a patient to develop a serious infection. That’s why it’s important that you pay close attention to every step of your work and ensure all tools are clean before giving them to the surgeon. Surgical technicians also must anticipate what the surgeon will need during each procedure, which requires an acute level of awareness.

Surgical technology is one of the fastest-growing fields in healthcare. With an aging baby boomer population and the increase in technological advancements, there is a need for skilled surgical technicians to support surgeons during operations. This is a career that can provide great satisfaction and a good salary, especially for those who want to work in the medical field.

When a surgeon requests a tool, the surgical tech must be ready to hand it over immediately, which requires a high level of concentration and anticipation. To prevent mistakes, you must keep track of the number of tools used during each procedure and make sure they’re all cleaned correctly afterward. It’s also essential to be familiar with the types of machinery you will encounter in an operating room, such as electrosurgical and electrocautery equipment, medical staplers, and argon beam coagulators.

A surgical technician is also responsible for applying bandages to patients and escorting them into recovery rooms. That requires the ability to stand for long periods of time, especially during emergency cases. Depending on the needs of a hospital, you may have to work nights or weekends, as well.

The work environment for a surgical technologist is usually clean and quiet, but it can be stressful because of the fast pace of operations. This is also a high-risk profession where you might be exposed to communicable diseases and unpleasant sights, smells and materials.

Assisting Surgeons

For surgical technologists, helping surgeons during surgery is one of the most important parts of their job. The operating room can be a hectic and dangerous environment, and even the most routine operation may take unexpected turns that require the surgical tech’s assistance. This is where the surgical tech’s knowledge of medical instruments, their proper use and the surgeon’s mannerisms come into play.

Surgical techs must also be able to keep their cool under pressure and respond quickly and appropriately to any issues that may arise during the procedure, from monitoring blood loss to changing sutures. This requires a great deal of concentration and the ability to focus without distraction. Surgical techs must also have good manual dexterity to maneuver tools, which can be bulky and cumbersome.

After the doctor finishes the surgery, the surgical tech takes a count of all the sponges, needles and other equipment used to ensure nothing was left inside the patient. This can be a tedious and time-consuming process, but it’s an important step to make sure no items are forgotten or left behind. The surgical tech may also help the surgeon apply dressings and aid in transferring patients into recovery rooms.

Because no two surgeries are alike, each day on the job for a surgical tech can be different. The fast-paced nature of the work can be challenging for some, but it can also offer more opportunities to learn and grow as a surgical technician.

Many surgical technologists receive their training in programs offered by community and junior colleges, vocational schools, hospitals, universities and the military. The length of these programs can vary, but most last from 12 months for a certificate to two years for an associate degree.

After graduating from a surgical tech program, some surgical technologists choose to further their education by earning a bachelor’s degree in healthcare, which can help them move up the career ladder and earn a higher salary. Others decide to pursue professional certification, which is available through many organizations that offer exam preparation courses. This provides a stepping stone to becoming a first surgical assistant or a supervisor, which can boost an already lucrative salary.

Post-Operative Care

Surgical technologists have a demanding job. They have to stay alert and stand or sit in the same position for long periods of time. They are also exposed to communicable diseases and unpleasant sights, smells, and materials. They are responsible for keeping the surgical environment clean and sterile. This can be challenging since surgeries happen daily and at any hour. Therefore, surgical techs must be willing to work nights, weekends, and holidays as needed.

It is essential for a surgical tech to be able to operate a variety of different types of surgical equipment. This includes lights, suction machines, and electrocautery devices. Surgical technologists also need to know how to properly use various suture techniques and pass tools to surgeons when asked.

Another essential skill for surgical technologists is the ability to communicate effectively with other members of the medical team. This can include relaying information about patients, answering questions, and completing paperwork. In addition, surgical technologists need to be able to listen carefully and respond quickly to any instructions from the surgeon.

In addition to being a fast-paced role, the surgical technician job is also highly rewarding. It can be satisfying to know that you are responsible for ensuring everything goes smoothly during a surgery. Whether that is the surgeon anticipating your next action or a circulating nurse waiting on you to give them a correct count of all the instruments used, there is always someone counting on you to get it right.

The best part about being a surgical tech is that the career does not require a bachelor’s degree. Most community colleges and vocational schools offer programs that last between nine and 24 months, and they usually combine classroom instruction with supervised clinical experience. In addition to learning the skills necessary for the job, students are taught anatomy, physiology, microbiology, professional ethics, and medical terminology.

It is important for a surgical technologist to be highly organized. This is because they are typically the first ones to enter a surgical room and set up the space for the procedure. They are then responsible for sterilizing and arranging all the needed tools and equipment.

Review

Types of Medical Assistant Jobs

Types of Medical Assistant Jobs

Medical assistant Jobs perform both administrative and certain clinical duties under the direction of physicians in healthcare environments. Here are just a few of the types of places where you could work:

Working in these clinics, you may encounter patients from all sorts of backgrounds, ethnicities, and ages. The experience of handling a variety of situations helps you develop great organizational skills, which can be important as you advance in your career.

Hospitals

Medical assistant Jobs are a vital part of the patient-centered medical home team, but they are also highly valued at hospitals and other ambulatory care facilities. In addition to clerical duties, like scheduling appointments, tracking treatment records and recording vital signs, MAs often perform clinical tasks such as explaining the physician’s instructions, collecting specimens for testing and performing phlebotomy.

Acute care hospitals never close, so working in this environment may require some evenings and weekends, especially when there are patients in need of emergency services. However, the fast-paced pace and variety of work can provide exciting challenges for those who enjoy a constantly changing workplace.

Located in the heart of the Midwest, Chicago is a leading hub for finance, culture, commerce, industry and technology. With a high number of MA jobs and a very affordable cost of living, this city is an excellent option for MAs looking to establish or continue their career in healthcare.

This large metropolitan area is well-known for its world-class museums, restaurants, hotels and attractions. It is also the second-best market for MA jobs and offers an affordable lifestyle, making it a top choice for medical assistants looking to establish their careers in healthcare.

The “City of Brotherly Love” is known for its rich history, diverse neighborhoods and welcoming people. It is also an excellent place to start a medical assisting career because it has the second-highest salary for MAs in the country, along with an average cost of living that is below the national average.

Medical assisting professionals may find employment opportunities in any of the many hospitals throughout the state, including those focused on cardiac care, family medicine and trauma. Some of the larger hospitals in this region include those at University of Maryland, Baltimore; St. Agnes Hospital; Johns Hopkins Bayview Medical Center; and Holy Cross Hospital. These hospitals offer a variety of career advancement and training programs for MAs who are interested in furthering their professional development.

Private Practice

Medical assistant Jobs perform a variety of tasks inside healthcare facilities and offices. While the exact duties vary based on healthcare setting, most jobs require similar administrative/clerical work such as updating patient records, processing insurance claims, and scheduling appointments.

In addition to these administrative duties, medical assistants often perform clinical procedures. They might draw blood for testing or administer injections. The responsibilities of a medical assistant can also include preparing patients for physical examinations, explaining test results to patients, and recording patients’ medical histories.

Another place medical assistants can find employment is at a podiatrist (foot doctor) clinic. These types of healthcare practices are usually smaller than hospitals, making it easier for medical assistants to develop close working relationships with patients. Medical assisting in this environment might involve a lot of foot-related tasks, such as cutting toenails and removing calluses.

A gynecologist’s office is another common workplace for medical assistants. In these settings, medical assisting might involve helping women with pregnancies and obstetrics, as well as providing general health care to gynecological patients. Some gynecologist’s offices may even specialize in women’s health, so a gynecologist assistant might focus on helping women with specific illnesses related to their reproductive organs.

Diagnostic laboratories are another type of medical facility where medical assistants can find employment. These facilities perform tests on biological samples such as blood, tissue, urine, and saliva. Depending on the needs of the lab, some positions may require a medical assistant to be certified as a phlebotomist.

Palliative care centers are places that treat terminally ill patients. These facilities are similar to hospital outpatient departments, but they typically offer more emotional and physical support for the families of the patients. Medical assisting at these types of facilities might require additional training to help patients cope with their conditions.

Another type of healthcare facility that offers jobs for medical assistants is a clinical research center. These types of facilities conduct clinical trials on participants to determine the effectiveness of new medicines and other treatments. As a medical assistant at one of these facilities, you might be required to assist research scientists in conducting these tests on the participants and record their findings.

Surgical Centers

As the healthcare industry continues to grow, medical assistants are gaining ground in facilities that might not be top-of-mind when thinking about jobs for medical assistants. For example, ambulatory surgery centers are growing and need medical assistants to perform the same types of administrative and clinical tasks as physician offices and hospitals.

These facilities also need people to handle patient scheduling and verifying insurance information. They need a person to coordinate and communicate with patients via telephone, fax and email. These professionals need to be good communicators, able to take directions and understand the delicate balance between administrative and clinical duties.

In some cases, a medical assistant may need to dispense medications and supplies under the direction of a physician. They may need to sterilize equipment in a procedure room. A person in this role may also need to assist physicians and patients during office visits, escorting them to exam rooms, taking vital signs and performing tests as directed by the physician.

Another area where medical assistants are starting to be utilized is in specialty care clinics. These include plastic surgery, dermatology and wound care centers. This is because these facilities need a person to help set up for surgeries and to handle patients before, during and after the procedures.

Those who work at these specialized facilities need to have the ability to adapt quickly and learn new tasks as the need arises. They must be a good team player who can adjust to changing circumstances and take directions from the physicians and nurses in the facility.

Some specialized medical assistants also find positions in the emergency room. While this is not a typical position for a medical assistant, these professionals are invaluable to the smooth operation of the ER. These individuals must be able to provide emergency support to incoming patients, and they must be quick on their feet to respond to any requests from the physicians and nurses.

In terms of the difference between nursing and medical assisting, the main distinction is that nurses have more scope of practice than a medical assistant. Nurses also make twice as much as medical assistants. In addition, a nurse will typically need to attend school for 2 years or more before becoming a registered nurse, which is an extensive commitment to the field of healthcare.

Outpatient Clinics

Medical assistant Jobs can find work in a variety of locations depending on their training and skill set. They perform both administrative and clinical tasks in ambulatory settings such as hospitals, private practices, and veterinary clinics. They can complete a variety of administrative duties including coding and billing, insurance claims and authorizations, preparing patients for physical examinations, taking and recording vital signs, and performing lab testing such as EKGs and phlebotomy. Clinical tasks may include establishing a patient relationship, taking patient histories, explaining medical procedures to patients, and scheduling appointments.

If you are looking to find a place to start your medical assisting career, outpatient clinics are a great option. They typically offer more consistent schedules than a hospital and often have a specific focus such as gynecology, dermatology, or chiropractic. This type of work can be ideal for people who have family or other commitments that require more regular hours.

Regardless of the location, all medical assistants need excellent time management skills to stay on top of their many responsibilities and be successful at their job. A large portion of a medical assistant’s day is spent answering phones, navigating computer systems, and managing the flow of patients. As a result, if you are not good at prioritizing and juggling multiple tasks at once, this may not be the best career choice for you.

Another disadvantage of being a medical assistant Jobs is that it does not provide a lot of room for growth. If you are looking to advance your education or salary, you will likely have to move into a different career path at some point in your life.

Overall, it is important to weigh the pros and cons of working as a medical assistant before you make your decision. If you are committed to this career and have the time and energy, it can be a very rewarding experience. Those who are not comfortable with the long hours or erratic schedule should consider pursuing a different field of work. However, if you are ready to get started and want to learn more about the exciting world of healthcare, Saint Luke’s welcomes you to apply for our medical assistant program.

Review

1999 Mitsubishi 3000GT/Stealth VR-4

1999 mitsubishi 3000gt vr-4

Nostalgia is big business, so old movies get remakes and old cars get reunion tours. Mitsubishi was smart and capitalized on the hype by reviving the 3000GT/Stealth VR-4.

The only high-end Japanese sports car to use a front-wheel drive chassis, the VR-4 benefited from a twin turbo iron block that was shared with everything from the New Yorker to the Diamante.

Drivetrain

In the 1990s, Mitsubishi took a gamble on something unique when they launched their 3000GT. The car was a radical departure from their more mainstream Eclipse and Starion models. Its bold looks were backed up with heavy technology including a 3.0-liter V6 twin-turbocharged engine, all-wheel drive, and four-wheel steering.

Mitsubishi made less than 300 of them for 1999, and this one stands out in its eye-catching Caracas Red paint with tan interior. It has a clean title and a reported service history with the seller.

This VR-4 has a pair of upgraded turbochargers that increase the factory power to 320 horsepower and 315 lb-ft of torque. The engine also features Mitsubishi’s MIVEC variable valve timing system. It was paired to a six-speed manual transmission and all-wheel drive. The VR-4 was the most powerful version of the 3000GT and competed with technological forerunners like the Acura NSX, Toyota Supra, and Dodge Stealth.

The VR-4’s all-wheel drive system and twin turbo V6 give it blistering acceleration, but the car’s hefty weight makes it prone to understeer when pushed hard. Even so, driving it is a joy. Twisting the key and watching the tach rise to the 7,000-rpm redline is an adrenaline rush. The car’s high top speed means you can wring it out on public roads without fear of a visit from the local constabulary.

It’s easy to see why the 3000GT VR-4 has become an icon of Japanese sports cars. With its muscular 320-horsepower twin-turbo V6, all-wheel drive, and awesome ’90s styling, it’s a true sports car. Its a shame Mitsubishi didn’t make more of them.

Nostalgia is a big business in the automotive industry, with old movies getting remade, bands going on reunion tours, and car makers bringing back hallowed nameplates like the NSX and GT-R. But the 3000GT hasn’t had much of a revival, perhaps because Mitsubishi is in deep financial trouble and doesn’t seem interested in making cars that leave a lasting impression. That’s a shame because the VR-4 is a fast, rare, and unique car. It’s a sports car that should have more fans than it does.

Exterior

The VR-4 is the most powerful Mitsubishi 3000GT ever produced and was only built for a few years, so finding one of these rare coupes in good condition is a rare treat. It features a muscular 320 horsepower twin-turbo V6, all-wheel drive, and awesome ’90s styling. The seller reports this specific example has only a few minor modifications and a clean Carfax history.

The Japanese automaker released the 3000GT in 1990 as a 2+2 seating grand touring sports coupe to compete with the likes of the Mazda RX-7, Nissan 300ZX, Acura NSX, and Toyota Supra. It was also sold under Chrysler’s Dodge brand as the Stealth in the United States.

This particular model is a 1995-3000GT SL Spyder that has a retractable hardtop and is finished in eye-catching Caracas Red with tan leather interior. According to the 3000GT/Dodge Stealth VIN database on 3SWiki, this was the last 3000GT VR-4 imported into the United States for the 1999 model year.

With only 287 examples imported, this is a desirable and collectable last-year model. The exterior is in excellent shape with a few scuff marks, but no major damage to report. It is equipped with 18-inch chrome plated alloy wheels, automatic climate control, four-wheel steering, and a Pioneer head unit. The seller has reported some minor modifications to the engine, including an ACT clutch kit and newer head gaskets.

Inside, the tan leather seats are in excellent condition and show minimal wear. The driver’s seat has adjustable bolsters and there are three gauges on the central dash. The steering wheel has a unique layout with radio controls on the bottom and cruise control buttons on top.

Driving a 3000GT is a fun experience. Its grip is prodigious and there’s plenty of power for anyone willing to push it to its limits. The suspension is tuned for handling and the cabin feels incredibly spacious for a sports car. It’s a great car to take to a Sunday show or attack your favorite back road on your own. The seller has a clear title in hand and this rare Japanese sports car could be yours for the right price.

Interior

Whether you’re cruising to a Sunday show or tearing down back roads, this is an amazing car. It might not have the prodigious grip of some modern sports cars, but it’s still a blast to drive. The engine has a nice rumble, and watching the tach swing to its 7,000 rpm red line is always a treat. The steering wheel feels like you’re in a racecar, with a firm, yet never harsh, feel to it. And those 18-inch chrome wheels are a great fit.

The VR-4’s 320-hp twin turbo V6 is quick to respond to your inputs, and the all-wheel drive system gives it a high top speed that’s hard to match. This car is so cool, and it deserves to be treated as such.

If you’re looking for a 90’s icon to restore or just enjoy as-is, this is the car. It’s fast, fun to drive and has a ton of style that will make people turn their heads. It’s also a very comfortable car, so it can be driven daily.

The first generation Mitsubishi 3000GT was built from 1990 to 2000. It was known as the GTO in Japan and the Dodge Stealth in North America. This car is one of the technological forerunners of its time, and it competed with other models such as the Acura NSX and Toyota Supra.

The second generation Mitsubishi 3000GT was introduced in 1997, and it kept the twin-turbo, 320-hp powertrain. This car was a little larger than its predecessor, and it also offered new headlights and a revised front bumper. This car was produced until 2000, and it was a competitor to the Honda S2000 and the Ford Mustang GT.

The third generation Mitsubishi 3000GT was updated for the 1999 model year, and it retained its twin-turbo, 320-hp performance. Its exterior was refreshed with a new front bumper and a rainbow-shaped, combat-style wing. This was the last 3000GT/Dodge Stealth made in the United States, and it was a great way to finish off an iconic model. This example is finished in Glacier White Pearl with a tan leather interior.

Performance

The VR-4 was the flagship of Mitsubishi’s performance lineup in 1990, replacing the Starion as the company’s top-tier sports car. Like rival models from Nissan, Toyota and Honda, it was a big and beautiful GT that packed cutting edge technology. The 3000GT featured a powerful DOHC 24-valve V6 with twin-turbos, all-wheel drive and four-wheel steering. It also had a tunable exhaust and active aerodynamics, which helped it to run quicker than the competition when blasted down a back-road by a skilled driver.

In fact, it was the fastest front-wheel-drive car of its era and a formidable competitor against rear-wheel-drive sports cars. Its 320-horsepower twin-turbo engine was mated to a six-speed manual transmission and had all-wheel drive.

As a result, it could blast from 0 to 60 in 5.80 seconds and reach a top speed of 159 mph. Its EPA-estimated fuel economy was 18 mpg in town and 24 mpg on the highway, which is not bad for such a high-performance car.

While the VR-4 was a capable performer on the track, its great mass tempered its handling abilities in tight corners. Its rear wheels often drifted during hard cornering, and its heavy brakes had a tendency to dive under power at frantic speeds. Despite its shortcomings, the 3000GT remains one of the most compelling Japanese sports cars of its time.

In its later years, the VR-4 saw a couple of facelifts and lost some of its gimmickry. The tunable exhaust was dropped in 1994, ECS was eliminated in 1995 and the active aero bodywork disappeared in 1996. Nevertheless, the VR-4 is still a fun and impressive sports car that looks as cool today as it did when it was new.

While it is not as desirable as a good example of the 1991-96 Dodge Stealth, which is mechanically identical to the VR-4, any unmodified VR-4 is an interesting piece of automotive history that you can enjoy on a Sunday drive or at the local car show. So grab a front passenger seat, crank up the tunes and enjoy this Mitsubishi’s version of the ultimate halo car.

-

Entertainment2 months ago

Entertainment2 months agoManga Life Review

-

Entertainment2 months ago

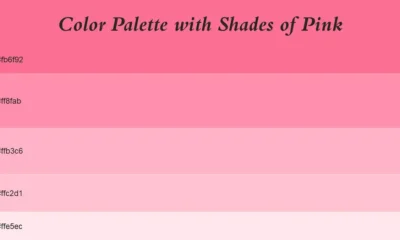

Entertainment2 months agoSalmon Pink Color

-

Entertainment2 months ago

Entertainment2 months agoHow to Use Google Scholar to Search Scholarly Literature

-

Entertainment2 months ago

Entertainment2 months agoMult34 – A Powerful Tool For Boosting Efficiency and Productivity

-

Entertainment2 months ago

Entertainment2 months agoWhat is the F74 Trend on Tiktok?

-

Entertainment2 months ago

Entertainment2 months agoHeardle Game Review

-

Entertainment2 months ago

Entertainment2 months agoBaddies West Where to Watch

-

Entertainment2 months ago

Entertainment2 months agoWhat Are the Different Types of Quizzes and Leaderboards?

-

Fashion2 months ago

Fashion2 months agoAcubi Fashion – A Seamless Blend of Minimalist Y2K Trends and Subversive Basics

-

Review2 months ago

Review2 months agoTypes of Medical Assistant Jobs

-

Entertainment2 months ago

Entertainment2 months agoAlexan Memorial Apartments – Live Life to the Fullest

-

Review2 months ago

Review2 months ago1999 Mitsubishi 3000GT/Stealth VR-4

-

Review1 month ago

Review1 month agoSurgical Tech Jobs

-

VR3 weeks ago

VR3 weeks agoVirtual Reality in Primary Education

-

Entertainment2 hours ago

Entertainment2 hours agoJames Avery Charms